제품소개

Sample Treatment—rushing / Homogenization/Dispersion

High-speed disperser

High-speed disperser

The instrument is operated by an electronic speed control and operated micro-high speed motor to drive the 316 stainless steel inner and outer plum-type crushing knives to work. The fixed rotor configuration is subjected to high-speed rotation of the in-cutting tool to homogenize, emulsify and crush various substances.

It is used for sample treatment such as sewage sample treatment, laboratory rapid homogenization and preparation of samples.

The machine is compact in design, equipped with high-speed AC motor, noise is less than 60 decibels, and the cutting tool is removable and easy to sterilize.

Main Technical Parameters

| Model | XHF-DY | The size of blade | Φ10mm processing volume:3-200ml; Φ14mm processing volume:50-500ml; Φ18mm processing; volume:50-1000ml; Φ25mm processing volume:100-2000ml |

| Power Supply | 220V/110V,50Hz/60Hz | ||

| Power | 360W | ||

| Adjustable range | 2800-28000rpm | ||

| Capacity | 3ml-2000ml | Display | LCD |

| Timing Range | 1-9.9min | Net weight | 8.0Kg |

| Ambient Temperature | -10℃-40℃ | Dimensions | 330×235×522mm |

S10 High-speed homogenizer (alias: tissue-pounding machine, powder-dispersive machine), is suited to liquid mixing, emulsion, homogenization dispersion of solid powder in a liquid, animal tissue crushing and homogenization. The machine is designed to bring about a strong hydrodynamic shear effect by means of high-speed shear force and speedy dispersion so that the material inhaled from the rotor bottom can spray through the stator. The extruded shapes suit ergonomics. It is easy to move and operate. As the minimum processing capacity can be 1ml, it is solely used for mashing organization, medical diagnostics, quality supervision, micro-dispersion, emulsification and homogenization. The device is ideal for micro-sample pre-treatment.

Main Technical Parameters

| Power | 160W | Processing Volume | 1ml-120ml |

| Power Supply | 220/110V 50/60Hz | Accessories | 10mm |

| Speed | 8000-35000rpm | Net weight | 1Kg |

| Display | OLED | Cutter reference processing capacity | Φ6mm, 1-10ml; Φ8mm, 2-50ml; Φ10mm, 30-120ml; |

| Speed mode | 28 levels adjustment | Optional accessories | working platform, container clamp、replaceable cutter(6mm、8mm) |

Application area

Biological / Biotech:Sonication is an ideal tool for lysing bacteria, yeast and tissue cells for the extraction of protein,DNA, RNA, and cellular components.

Pharmaceutical:Cell disruption is common in analytical, quality control, and R & D labs to perform numerous functions from mixing and degassing of analytical samples, to cracking open tablets for dissolution tests. Liposomes and emulsions are easily formed by Sonication for microencapsulation purposes in the production of creams and lotions.

Chemical:Sonication accelerates both physical and chemical reactions. Major advances in sonochemistry include chemical synthesis of catalysts and new alloys, catalyzing organo-metallic reactions, micro-encapsulation of protein and hydrolyzing esters. The use of sonication provides greater yields, increases overall efficiency, and saves energy.

Industrial:Industrial uses include forming emulsions, catalyzing reactions, extracting compounds, and reducing particle size.

Environmental:Sonication is used by environmental testing labs to process soil and sediment samples.Sonication takes just 8-10 minutes per sample versus 4-18 hours by soxhlet extraction, it uses half the solvent and improves contaminant yields.

Main Technical Parameters

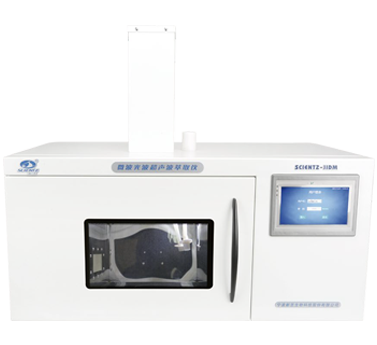

| Model | SCIENTZ-IIDM |

| Microwave power | 1000W (1%-100%) |

| Microwave frequency | 2450MHz |

| Microwave working time | 0-999S |

| Microwave action mode | pulse continuous heating |

| Light wave power/wavelength | 0-800W/infrared segment |

| Light wave working time | 0-999S |

| UV light power/wavelength | 50W/365nm |

| Ultrasonic horn diameter | Φ8mm |

| Ultrasonic power/frequency | 10-1000W/20-25 KHz |

| Ultrasonic action mode | the immersion ultrasonic transducer is in direct contact with the material in the container, and th e acoustic vibration (energy) efficiency is close to 100% |

| Magnetic stirring | 50-300 rpm |

| Program control | 200 groups of programs can be preset, each program can preset time (0-999S), microwave, light wave, ultrasonic power, ultraviolet (on/off), stirring and other control working parameters, computer storage, can be set directly , modify and call; |

| Temperature control | non-contact infrared temperature measurement. Temperature and temperature control range, room temperature ~ 300°C (± 1°C) |

| Machine control | Full Chinese true color touch screen man-machine interface, industrial-grade microcomputer PLC programmable controller |

| Password | user, administrator secondary password |

| Reflection monitor | integrated screen with real-time video window to monitor sample reaction status |

| LED lighting power/color temperature | 24W/6200K |

| Network interface | RJ45 |

| Sample volume | standard 500, 1000mL (special specifications can be customized according to user requirements) |

| Protection | It has multiple safety interlock protection devices such as magnetron temperature protection and door switch protection, with high reliability and safety |

| Material | stainless steel inner shell, durable |

| Furnace chamber volume | 25L |

| Power supply | 220V±10%AC, 50Hz; Power: 3000W |